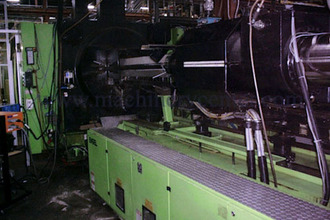

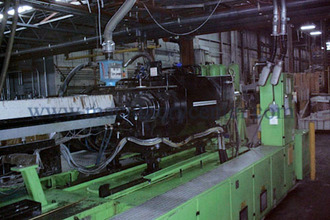

1000 Ton, 209.2 Oz. Engel Injection Molding Machine '00

Injection Molders 901 Ton & Over

1000 Ton, 209.2 Oz. Engel Injection Molding Machine '00

Model: ES11050/1000 WP

Beautiful Condition!!!!

| Year | 2000 |

| Tonnage | 1000 |

| Shot Size | 209.2 |

| Platen Size | 83.23" x 77.56" |

| Tie Bar Spacing | 60" x 45.28" |

| Mold Height (Min) | 15.75" |

| Mold Height (Max) | 39.37" |

| Daylight | 15.75"/78.74" |

| Ejector Stroke | 11.81" |

| Clamp Stroke | 39.37" |

| Screw Diameter | 120mm |

| LD Ratio | 24:1 |

| Core Pull | Yes |

| Control | CC100/A03 |

| Dimensions | 591.56" x 114" x 135.2" |

209.2 Oz. Injection Unit

Standard Paint m/c it green (EC#5007) & black (EC5001) clamp assy Pump/motor platform-lrg mcs only

3. Levelling & vibration mounts

Bilingual warning labels in English & French (ipos)

Auxiliary bypass oil filtration.

SPI Safety key switch.

4 x air blow off with timer & ½" 3-way valve 2 on stationary & 2 on moving platen.

Hydraulically actuated mold valve gate shut-off via accumulator.

Double corepull/rack & pinion unscrewing.

Platens prepared for retrofit of QMM.

Ultramax bi-metallic barrel (in place of standard)

Increased hydr. drive-improved plasticizing, faster speed/cycle.

Accu pig for incr inj speed c/w ind. Charg’ incl EOF-CC100 mcs.

24:1 ENGEL MeltPro Barrier screw 4140 base steel, Colmonoy #86 weld flight land, chrome

plated root and Pulsar mixer/adder (pos).

Power capacitor.

Mineral insulated heater bands.

Power conditioner for triacs.

Alarm bell and re-set switch.

2 x 115/1-60 (15 amps max.) Duplex outlet; 1 located on operator side of control panel location

“E”; 1 located on operator side gate assembly.

230/3/60 - 30 amp Hubbel #2720 outlet located on right hand of AC panel, location “F”.

CC100 Microprocessor.

CC100 Level 2 Software.

CC100 Microgplast/Microflow Processing Software.

CC100 Micrograph Plus.

CC100 Process Data - Graphics and Reports.

Ejector back confirm’n input signal (does not incl, limit switch.

16 x CC100 PID mold temperature control zones.

Re. option # 1134, 15 amps each, multi-plug DME located inside gate on non-operator side.

Closed loop feed throat cooling control:

CC100 8 Zone temperature control card.

Engel RC100 robot interface includes cycle start button.

Conversion from English to French text - instant.

Robot operator side deposit.

Special key switch (per confirmation 12/8/00).

Extended ejector plate to handle ejectors at 508mm from the center.

Grease nipple required on extended ejector plate at each guide bar.